- Goals of the brand's ongoing environmental program adjusted upwards

- 45 instead of 25 percent reduction in CO2 emissions, energy and water consumption, waste production and solvent emissions aimed for, compared with 2010

- Production Board Member Thomas Ulbrich: "We are on the way to the resource-optimized factory."

The Volkswagen brand has set itself new, ambitious targets for reducing the environmental impact of production. By 2025, vehicles and components are to be produced in a way which is 45 percent more environmentally compatible than in 2010, the reference year for the current Think Blue. Factory. environmental program. This was announced by Thomas Ulbrich, Member of the Brand Board of Management responsible for Production and Logistics: "We reached our environmental target of producing our vehicles 25 percent more sustainable by 2018 before the date set. We now intend to reduce environmental impact by a further 20 percent by 2025. We are on the way to the resource-optimized factory at all the locations of the brand."

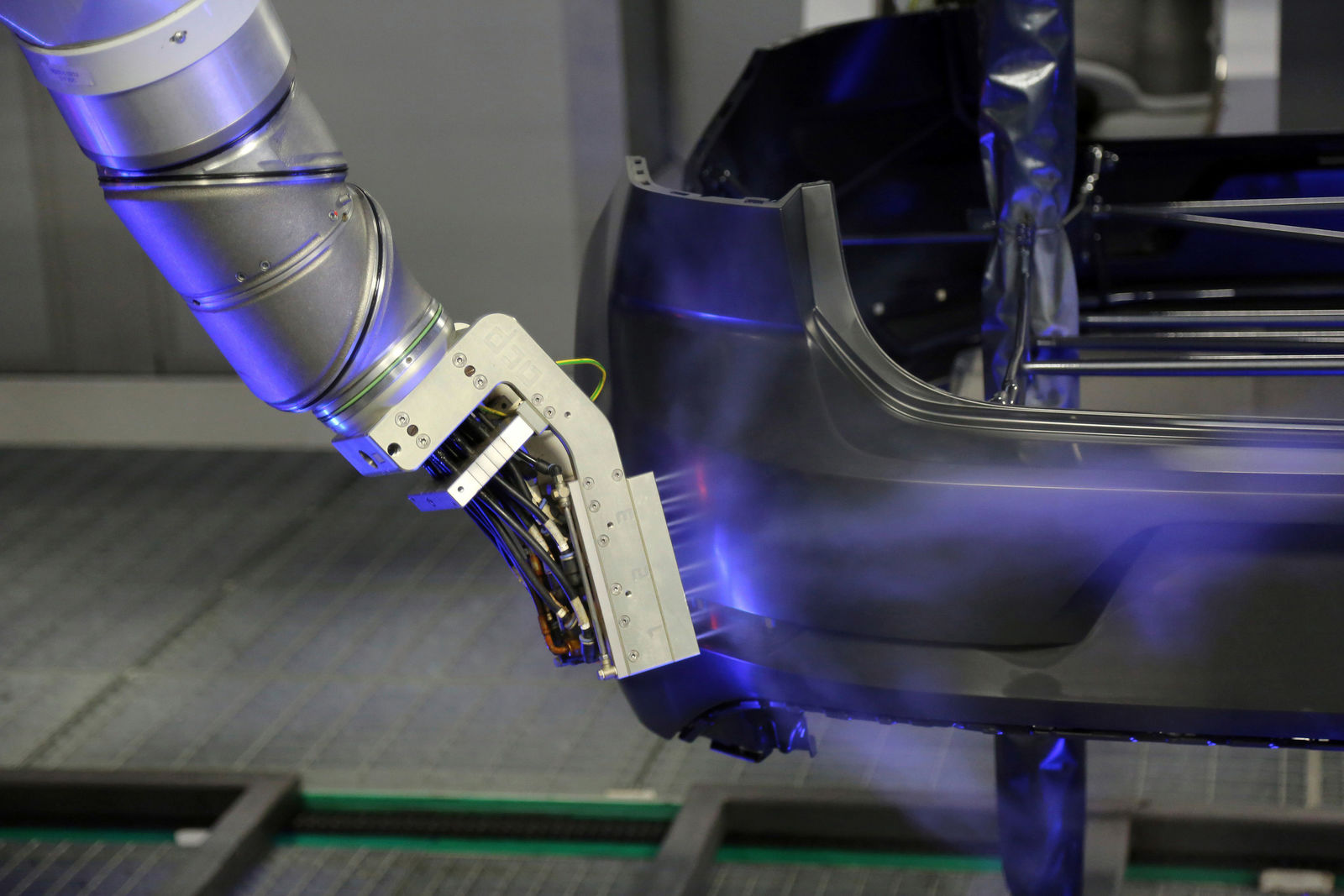

With Think Blue. Factory., Volkswagen launched the first program for environmentally sustainable production. 5,300 measures to reduce emissions and use resources more efficiently have been implemented. 16 existing paint shops have been optimized and the base load energy consumption of the plants during non-production times fell by 15 percent on average. Eight international locations have taken 100 percent of their power requirements from renewable sources since the start of the program. Thanks to lower consumption, the environmental program has already saved more than €130 million in production throughout the world over a period of six years.

Thomas Ulbrich: "One of the reasons why we are setting ourselves new, higher targets is that our team identifies with our environmental program and is making an outstanding contribution. The results are due to interaction between good ideas of our employees, targeted investments in the latest environmental technology and enthusiasm for process optimizations."

The approach adopted means that the plants which form part of Volkswagen's global production network systematically exchange information on their respective success stories and adopt the most appropriate measures from each other. In future, not only compressed air systems, cold networks and cooling towers but also ventilation and lighting systems are to be reviewed at all locations with a view to achieving further savings.

The Volkswagen brand is not only adapting its environmental targets in quantitative terms but also in qualitative terms. It will be basing its targets more closely on the Paris Climate Agreement and the Sustainable Development Goals of the United Nations. Dr. Liendel Chang, Head of Environmental Production, explained: "To date, we have given equal weighting of 20 percent to each of our environmental indicators. This corresponded to 40 percent for the global climate protection factors CO2 and energy, and 60 percent for the local environmental protection factors of water consumption, waste production and solvent emissions. In future, the weighting will shift to 60 percent global and 40 percent local."

To date, Think Blue. Factory. has received more than 30 awards – including the National Energy Globe as the best project in Germany, the GreenTec Award for energy efficiency and water-saving measures in production and the Sustainovation Award. As of the end of 2016, Volkswagen has achieved an average reduction of 29.2 percent in environmental impact: energy -23.5%, CO2 - 28.6%, waste -58.6%, water -27.5% and solvent emissions -7.6%.

Media contacts